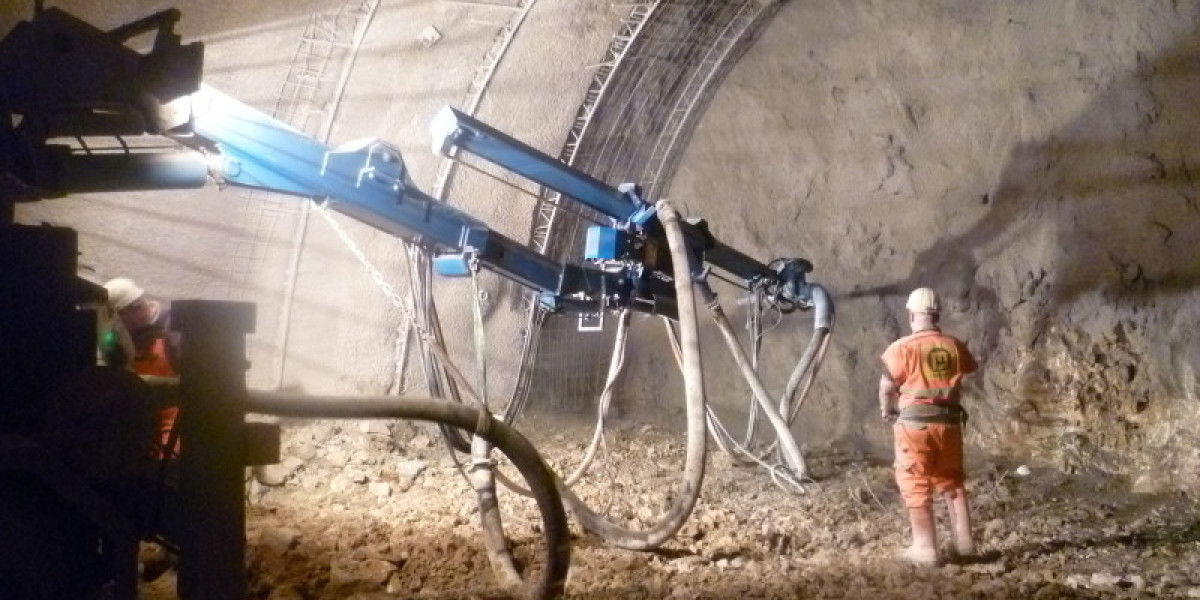

Shotcrete has revolutionized construction and mining, especially in underground mining operations, where stability and safety are paramount. Its versatility, efficiency, and durability make it an ideal solution for reinforcing tunnels and underground structures. In this article, we delve into the role of shotcrete in mining and explore its cost per square meter to help you plan your projects effectively.

What is Shotcrete?

Shotcrete, also known as sprayed concrete, is a high-performance concrete applied pneumatically through a hose onto a surface. It’s commonly used for reinforcing rock, soil stabilization, and creating structural linings in underground mining.

Types of Shotcrete

Wet-Mix Shotcrete

Pre-mixed concrete is pumped to the nozzle, where compressed air propels it onto the surface.

Preferred for large-scale applications due to consistency and reduced dust.

Dry-Mix Shotcrete

Dry materials are conveyed to the nozzle, where water is added just before application.

Offers greater control over water content but generates more dust.

Role of Shotcrete in Underground Mining

Rock Support

Shotcrete acts as a protective layer, preventing rockfalls and stabilizing tunnels in mining operations.

Durability in Harsh Environments

Its resistance to water, chemicals, and high pressures makes it suitable for underground conditions.

Rapid Application

The spray-on process allows for quick reinforcement, reducing downtime in mining projects.

Versatile Usage

Shotcrete can be applied to uneven surfaces, making it ideal for the complex geometries of underground mines.

Advantages of Using Shotcrete in Mining

Safety: Enhances structural integrity, minimizing the risk of collapses.

Efficiency: Faster application compared to traditional concrete placement.

Cost-Effectiveness: Reduces the need for extensive formwork.

Adaptability: Can be applied in various thicknesses to meet specific reinforcement needs.

Shotcrete Price Per Square Meter

The cost of shotcrete price per m2 varies based on factors like material type, application method, and project scale.

Factors Affecting Price

Material Costs

High-quality aggregates, cement, and additives influence the overall price.

Application Type

Wet-mix shotcrete is typically more expensive due to equipment and labor requirements.

Thickness of Application

Thicker layers increase material usage and labor time, raising costs.

Project Location

Transportation and site accessibility can impact pricing.

Average Cost Range

Wet-Mix Shotcrete: $80–$120 per m² (depending on thickness and materials).

Dry-Mix Shotcrete: $60–$100 per m² (slightly cheaper but more labor-intensive).

Optimizing Shotcrete Costs in Mining

Accurate Planning

Determine the required thickness and coverage to avoid overuse.

Material Selection

Use cost-effective materials without compromising quality.

Skilled Workforce

Experienced workers ensure efficient application, reducing waste.

Regular Maintenance

Routine inspections and repairs prevent the need for extensive replacements.

Applications Beyond Mining

While underground mining remains a primary use case, shotcrete is also widely used in:

Tunnel construction.

Slope stabilization.

Retaining walls.

Swimming pools and decorative features.

Conclusion

Shotcrete is a cornerstone of underground mining, offering a safe and durable solution for structural reinforcement. By understanding its costs and applications, you can optimize your mining or construction projects for both performance and budget.