Water Tank Painting: Which Paint is Best for Steel?

Water Tank Painting: Which Paint is Best for Steel? Industrial coating companies for reservatorio metalico Cilindrico inner floor are very labour-intensive. This is connected with difficult procedures of floor preparation and making use of corrosion safety coating for metal. It’s important for tanks that store potable water to comply with ANSI/NSF Standard sixty one for Drinking Water System Components, which most US states and Canadian provinces both require or suggest. Standard sixty one covers various components of water remedy and distribution systems, together with protecting barrier supplies like paints and coatings. Use high-temperature, rust-resistant spray paint designed for metallic surfaces. These paints withstand warmth and might endure the elements, reservatorio metalico cilindrico preventing rust and fading over time.

Katy Water Tanks

After it’s in place, it doesn’t need plenty of downward strain; the fluid retains the liner taut. If it’s too chilly, the crew might make detrimental errors as a result of shivering or stiff fingers. The greatest time to perform silo portray is when it is a reasonable temperature outdoors. It’s important to complete every step of the metal construction painting process because improper painting will trigger points over time. Inside Coating Systems 3 and 4 (ICS No. and No. 4) are thought of to have a service life approaching thirty years. These long-lasting lining methods have been proven to minimize back life cycle prices for municipalities and privately-owned water methods.

The Appeal of Steel

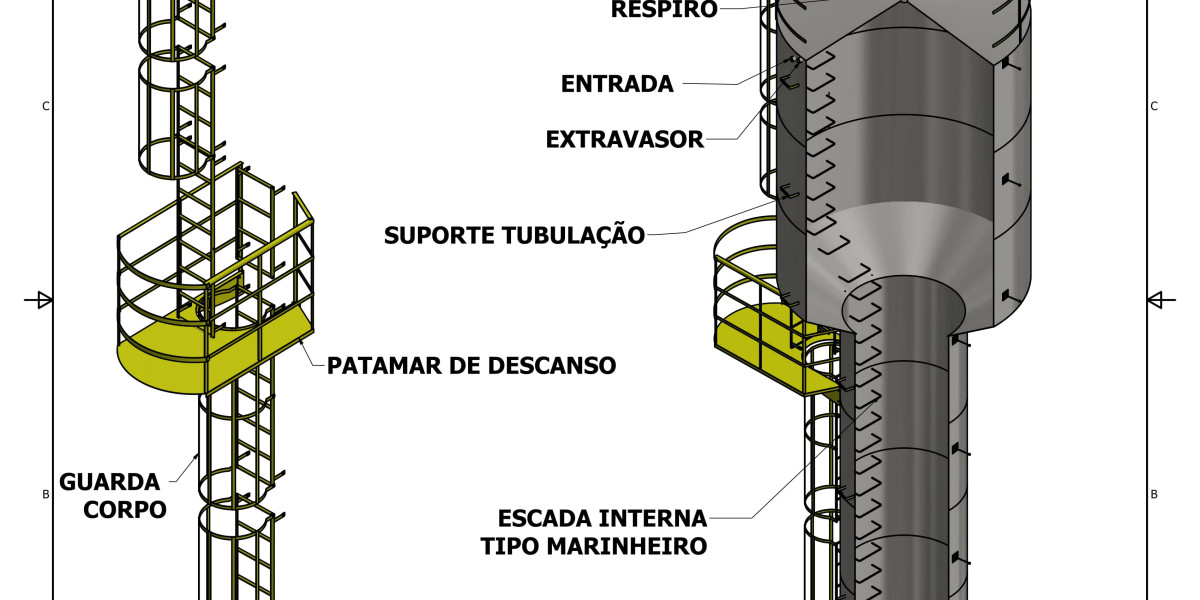

An added good factor about tank coatings and linings is that techniques for tank interiors are available with low-to-zero VOC’s, thus eliminating any considerations over style and odor issues trigger by solvents. Two examples of these coating techniques can be discovered within the AWWA D102 Standard, Coating Steel Water Storage Tanks, as Inside Coating System (ICS No. 3) and Inside Coating System (ICS No. 4)2. Most tank cleansing and coating initiatives usually are not DIY initiatives; they're just too dangerous, to not mention the technical skills required. Just one have a glance at the image above, from certainly one of our water tank initiatives, and you can perceive why. These are a few of the distinct concerns a contractor must account for before starting a project involving storage tank painting and coating. There are hundreds of coating requirements for several types of storage tanks and how they are utilized.

The removable water filter is good, but it’s not front-loading. Meaning, you must take away the reservoir from the top. Not perfect if you don’t wish to danger bumping into your cupboards. The buttons are also tiny, which isn’t great for folk with massive fingers. Its SCAA certification ensures a high-quality brew, whereas its BPA-free and dishwasher-friendly carafe ensures ease of use and security.

Metal garage building kits present a quick a cost-effective work space without sacrificing appearance. Fencing and Gates – Rectangular tubing is commonly utilized in fencing and gate building for its power and aesthetic enchantment. In this article, we’ll go over a few of the most common makes use of for metal tubes, so you could get a greater concept of what they’re all about. Green Energy Structures – Rectangular tubes are employed in frameworks for solar panels and wind turbines, balancing sturdiness and weight efficiency. Purchase it online or at any Metal Supermarkets location, cut to your exact specifications. At Wattco, we now have a dedicated team of experts ready to provide you with the answers and assistance you want.

Metal garage building kits present a quick a cost-effective work space without sacrificing appearance. Fencing and Gates – Rectangular tubing is commonly utilized in fencing and gate building for its power and aesthetic enchantment. In this article, we’ll go over a few of the most common makes use of for metal tubes, so you could get a greater concept of what they’re all about. Green Energy Structures – Rectangular tubes are employed in frameworks for solar panels and wind turbines, balancing sturdiness and weight efficiency. Purchase it online or at any Metal Supermarkets location, cut to your exact specifications. At Wattco, we now have a dedicated team of experts ready to provide you with the answers and assistance you want.Concrete tanks, in contrast, could expertise erosion of inside surfaces as ice grinds up and down the interior sides of those tanks and "knocks off&lrdquo; the substrate. FRP and concrete tanks could crack and leak, while steel tanks may be protected with linings that meet AWWA Inside Coating System (ICS) No. four. These NSF 61-certified elastomeric linings present excessive protecting movie thickness and elasticity throughout their service life – which is measured in decades. Tank portray jobs typically require a recent coat for both the within and outside of the tank or tower. The want for fall protection on lofty, iconic water towers corresponding to those we’ve painted at Alsip or Two Harbors is obvious. But even ground-level tanks like the one at Eglin Air Force Base rise a quantity of stories off the ground and necessitate security methods be in place. The Water Regulations Advisory Scheme (WRAS) should approve any tank or coating substance before use.

AST Tank Bottom Coating / Floor Pan

A priming coat is utilized on the ready inside tank floor with a pneumatic spray gun. This process is meant for guaranteeing adherence of the paint coating with the metal. In my expertise, the longevity and performance of Tnemec coatings are superior, which is necessary, given the excessive visibility of water tanks. Applying primer prepares the tank’s surface for paint and enhances adhesion.